Recover

Recycle

Reuse

PCWflex reuses plastic waste to create next generation polythene

With the environment at the forefront of our thoughts, we have continued to focus on green film technology and we are very pleased to launch our exclusive range of PCWflex films – all containing post-consumer waste (PCW).

Next generation polythene

Polythene containing Post-consumer waste reduces the consumption of fossil fuels (used to produce virgin grade PE), they also dramatically reduce the amount of packaging waste going to landfill, filling our oceans, and polluting the environment. The aim here is to reduce pollution and increase levels of plastic recycling, helping to remove the issue of single-use packaging, our closed-loop manufacturing process keeps resources in use for as long as possible with a continuous loop of environmental recovery, recycling and reuse.

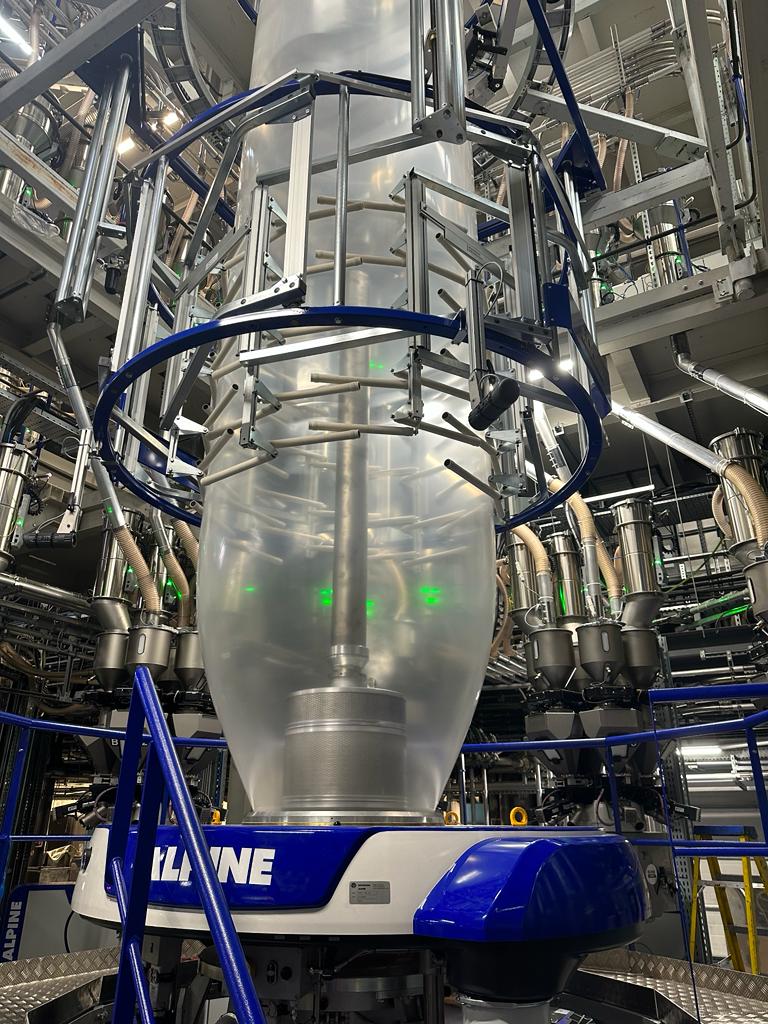

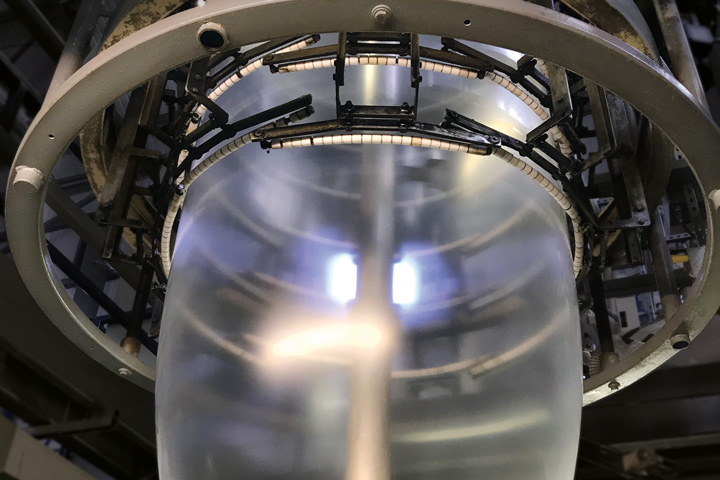

PCWflex films incorporate UK sourced Post-Consumer Waste which has been collected, washed, shredded and re pelletised. With technical film types, this recycled polymer can be used in the middle layer of a co-extruded film structure, which will then not affect clarity or performance.

By using recipes that contain various amounts of recycled polymer, PCWflex technology delivers the same mechanical properties as virgin grade PE and can be applied across our product range. Non-Shrink Films start at 30% but can contain up to 100% PCW polymers, and our shrink film recipe can include an impressive 50% PCW polymers without losing any of the functionality you would expect – whilst all remaining 100% recyclable!

What does post-consumer waste mean?

Post-Consumer Waste is material that has served its intended purpose as a consumer item, and has then been separated from other material, which is to be disposed of. Post-Consumer Waste has completed its life cycle as a consumer item and can now be recycled and reused.

Why add it to polythene?

As part of its effort to tackle ongoing problems with litter and waste from single use plastic, the UK Government has introduced PPT (Plastic Packaging Tax) on plastic packaging that contains less than 30% recycled material.

Therefore, PCWFlex acts as a solution to this tax by improving the lifecycle of single-use polythene by introducing post-consumer waste within the blend, improving recycling and pollution.

This material is popular with these products:

Collation Shrink Film

Secure your products using low-density polyethylene (LDPE) collation shrink film for a cost-effective, efficient, versatile packaging solution.

Plastic Shrink Covers

Primarily used in single wound, centrefold, and multi-fold formats, Polystar manufacture high quality, heavy duty plastic shrink wrap suitable for both manual or automated applications.

Furniture Bags

We manufacture a vast range of plastic furniture covers specifically for the furniture and bedding sector.

Pallet Covers and Top Sheets

Pallet covers are the most cost-effective way of ensuring your products remain dry and dust-free.

General Tubing & Sheeting

Our range of polythene tubing provides ideal polythene formats for the packaging of a variety of products with abnormal or long dimensions.

Polythene Bags

Polystar are able to produce a wide range of plain and printed polythene bags specific to your requirements.

What types of products can use PCWflex?

Collation Shrink Film

Secure your products using low-density polyethylene (LDPE) collation shrink film for a cost-effective, efficient, versatile packaging solution.

Polythene Shrink Covers

Primarily used in gusseted, centrefold, and multi-fold formats, Polystar manufacture high quality, heavy-duty polythene covers and film suitable for both manual or automated applications.

Furniture Bags

We manufacture a vast range of Polythene furniture covers specifically for the furniture and bedding sector.

Pallet Liners and Top Sheets

Pallet covers liners and top sheets are the most cost-effective way of ensuring your products remain dry and dust-free.

Stretch Hooding

This is our latest product to have a PCW (post-consumer waste) inclusion at 30%, despite stretch hooding being a very demanding product in application. There is no effect on performance with Polystar’s high-performance blend – PCW Flex.

General Tubing & Sheeting

Our range of polythene tubing provides ideal polythene formats for the packaging of a variety of products with abnormal or long dimensions.

Polythene Bags

Polystar can produce a wide range of plain and printed polythene bags specific to your requirements, for food grade and industrial sectors.

The Importance of Post-Consumer Waste

As an example – Polythene bags or FFS (form fill and seal) film are used for a range of poly bag requirements both, across all market sectors. Types such as form fill & seal film for food and agricultural markets, clear polythene bags used for packaging and storage, and also as heavy-duty waste bags and government-approved waste bags used as traditional waste and refuse bags.

The consumption of this particular polythene means the need to facilitate a more environmentally sound solution is high. More than 160,000 plastic bags are consumed each second with 10% ending up as waste in the ocean.

With this, PCWFlex provides a solution to improve the overall lifecycle of single-use polythene and recycling general.

Benefits of replacing single-use plastics with PCWFlex?

Reduce Plastic Going to Landfill

For every single-use plastic bag that is made, there’s 1000 years of plastic pollution associated with that bag. Switching to PCWFlex as an alternative plastic bag manufacturer ensures better plastic recycling and less impact on the environment long term.

Reduce Plastic in Our Oceans

A global issue, reducing plastic waste going into our oceans will improve ocean pollution and animal safety by not polluting these natural habitats and providing a solution for waste through direct plastic recycling.

Reduce Cost Implications to your Business

Through the use of PCWFlex, your business has the opportunity to reduce the potential for tax payments on plastic without post-consumer waste by using an alternative product that includes the minimum requirement of 30% or more of post-consumer waste.

+44 (0) 2380 232153

+44 (0) 2380 232153